Summer Research Dispatch: Tina Piracci on 3D Printing with Germinated Spores

Each year, the Berkeley Center for New Media is thrilled to offer summer research awards to support our graduates in their cutting edge work. Below, Tina Piracci describes how she used the funds for research on 3D printing with germinated spores.

As a Master of Science in Architecture student focusing on technology and sustainability, my work is centralized around 3D printing natural pastes and how materials research can yield specific desired results. After a recent exploration of growing edible mushrooms from home, I have become interested in creating a recipe which would allow the printing of an object consisting of a substrate for growth as well as germinated spores to yield a vase like object that would be able to grow mushrooms from its surface when exposed to water and in direct sunlight. Applications could be expanded from the vase form to potentially a brick like object for installations or mushroom walls.

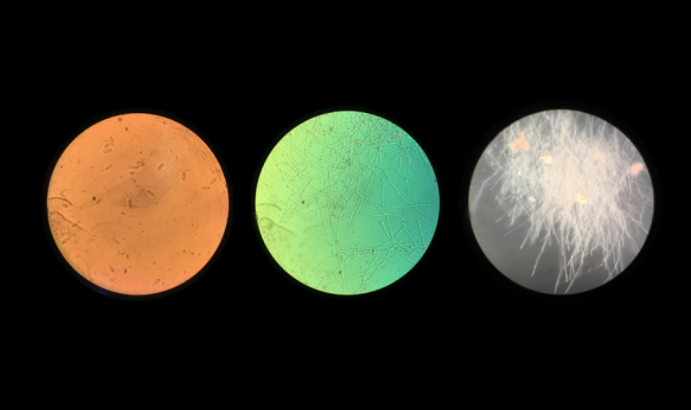

The images above are studies completed with 5” x 10” x 6” impregnated mycelium bricks purchased online. These structures are premade for gardening at home and contain sawdust, straw and germinated mycelium. Their growth and harvest process are very fast as the time between opening the kit and harvesting, as seen above, occurred over 8 days. This, along with information gathered online, raised initial concerns about the scale of the substrate, since the goal was to print hollow objects and these bricks have a wider girth than the printed “vases” would hold. The images from the title page include microscopy images gathered in Professor Bruns laboratory of the oyster spores used for the experiment below at various stages of progression including: spore, dikaryon, and mycelia tissue.

Though the recipe is still not complete, the research yielded promising information in terms of the project’s feasibility and outcomes. The most valuable findings included the familiarity of the fragility of the spores before they germinate as many of the tests, as seen in the first two images to the right, started to grow and then were outbattled by mold growth. After discussions with a mushroom lab in Oakland, I learned that this is the most fragile and challenging stage. In order to create a paste in which is able to be extruded, I must find the ideal balance that will allow the mycelia to successful grow with limited competition. Materials experimented with included: recycled sawdust, wheat paste, DIY rice paste, straw, rye seeds, flour, sugar, methyl cellulose and used coffee.

Another valuable finding was the necessary thickness of substrate necessary to successfully harvest oyster mushrooms. Surprisingly, small bits of the impregnated mycelia brick still were able to yield viable mushrooms, lending the ability to potentially print hollow objects. The samples displayed below are approximately 1” x 1” and are housing premature mushrooms.

Ideally, the final work would utilize Lucy & Ethyl, the Kuka arms in Jacobs Hall as this is where the research originated in Spring 2020 for the Robotic Fabrication course. Located in the basement of Jacobs, this environment reduces sunlight providing an ideal space to culminate mushrooms. The advisers in Jacobs have provided strict guidelines to follow for the allowance of this project. This series would be a 3-stage performance including: Creation, Growth, and Harvest.

Stage 1: Two Kuka arms would extrude several vase-like abstract forms with the paste deposition and allow them to dry. This would be programmed in both Mimic for Maya and Grasshopper for Rhino to combine both a thoughtfully choreographed toolpath (Mimic) and the programmed object (g-code produced with Grasshopper) in order to lend a more anthropomorphic motif. With two robots producing two sets of “vases,” one set of the creations will be set aside.

Stage 2: Using one half of the “vases,” and setting the other half aside to remain dormant for guests, the arms would mist the sporal forms twice daily in a caring and thoughtful manner. After about 1-2 weeks, the fast-growing mushrooms would be ready to harvest.

Stage 3: Welcoming 1-2 participants, the Kukas would then pick and cook the mushrooms in a frying pan for their dinner guests. Using OpenCV and tracking, the Kuka arms would then locate and pick the mushrooms. Though this would take thorough programming, oyster mushrooms are tough in texture and simple to pick as they come off easily in clusters once reached maturity. Then, through more painstaking programming, the Kuka arms will work together to break and sautee the mushrooms for its guests. The guests will then be served the fine mushrooms and will be given the pairing vase to be able to grow the mushrooms from home. The room will then be sanitized and welcome the next guest.